qlsensor.com

C2YF03- load cell internal transmitter /RS485 communication/analog output

C2YF03- load cell internal transmitter /RS485 communication/analog output

Couldn't load pickup availability

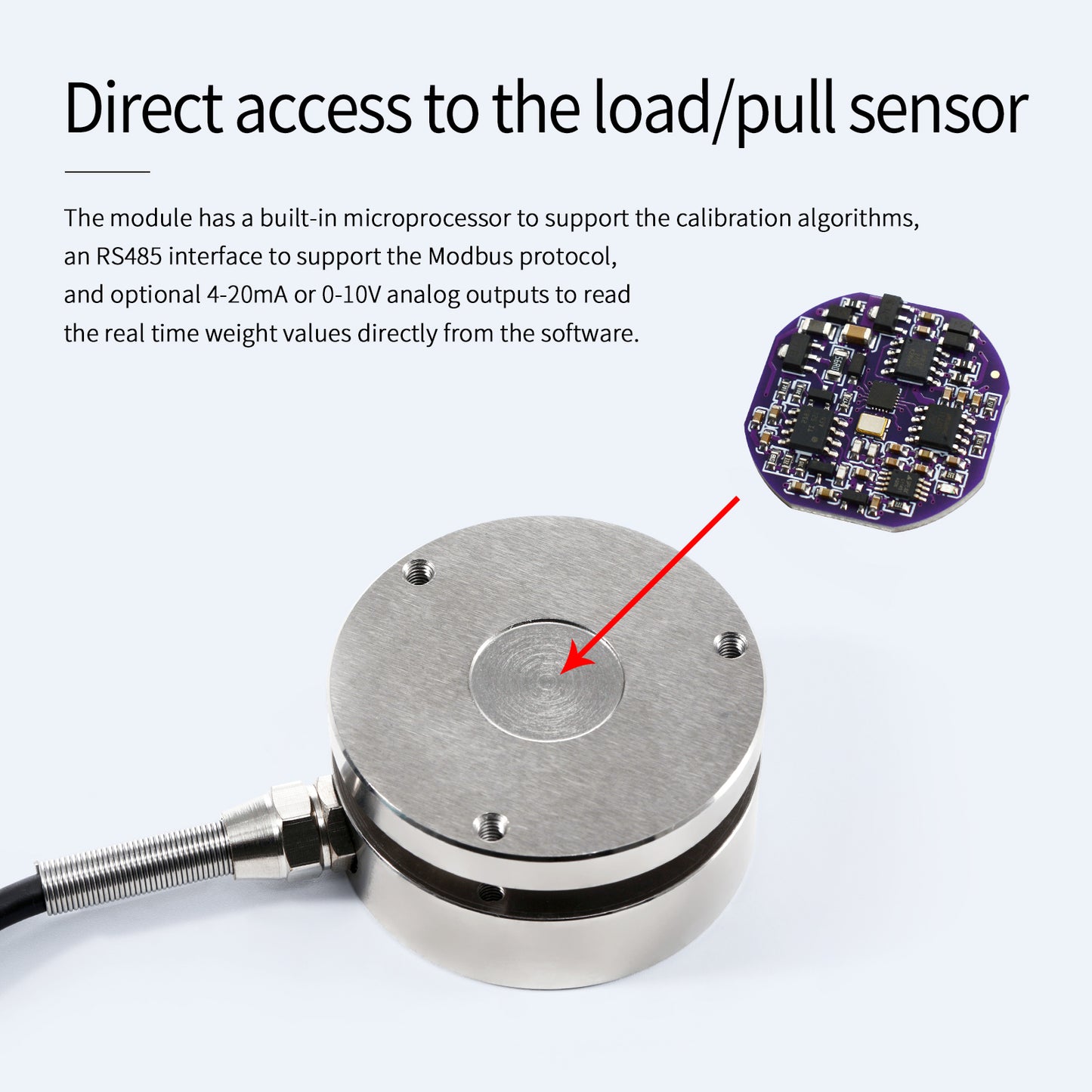

Weighing Sensor with Built-in Transmitter: The Industrial-Grade “Nervous System” for Precise Measurement and Control

In complex industrial weighing and data acquisition scenarios, a precise, stable, and highly adaptable signal processing core is of critical importance. This weighing sensor with a built-in transmitter, with its outstanding performance, lays a solid foundation for data acquisition and transmission in various weighing systems, serving as a reliable “nervous system” in industrial measurement and control processes.

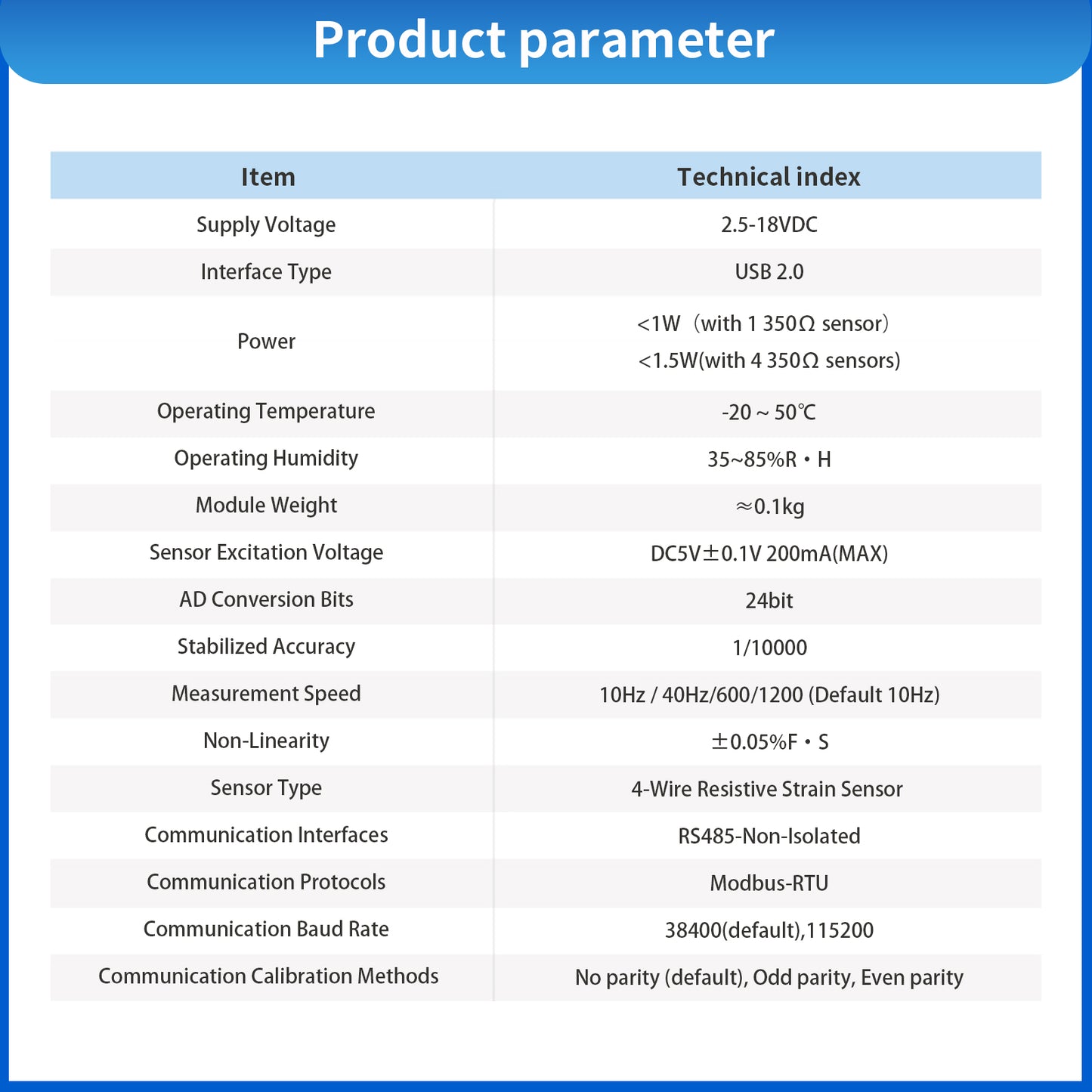

1. Flexible power supply and interfaces for diverse applications

(1) Wide voltage compatibility for robust power supply compatibility

Supporting a wide voltage range of 2.5–18 VDC, it can easily handle power fluctuations in various environments such as factory workshops and outdoor operations without requiring additional complex power conversion equipment. Whether integrated with small industrial control computers or adapted for mobile detection devices, it ensures stable power supply and continuous system operation.

(2) USB 2.0 Interface for Efficient Debugging

Equipped with a USB 2.0 interface, it can be quickly connected to a computer for parameter configuration, data debugging, and firmware upgrades. Engineers do not need specialized adapters and can efficiently operate in laboratories or production line sites, significantly reducing system debugging cycles and improving project delivery efficiency.

II. Low-power design, energy-efficient and reliable

Precise power consumption control tailored to different sensor loads: when paired with a 1350Ω sensor, power consumption is <1W; when using a 4350Ω sensor, power consumption is <1.5W. In industrial scenarios requiring continuous operation, this effectively reduces energy consumption, aligning with green production principles, while also minimizing device heat generation, enhancing system stability, and extending service life.

III. Environmental resilience, suitable for complex operating conditions

(1) Wide temperature and humidity adaptability

Operating temperature range: -20°C to 50°C; humidity range: 35% to 85% RH. Whether in cold warehouse logistics weighing or high-temperature, high-humidity food processing and chemical production lines, it operates stably, ensuring weighing data collection is unaffected by environmental interference, and safeguarding precise measurement and control in harsh conditions.

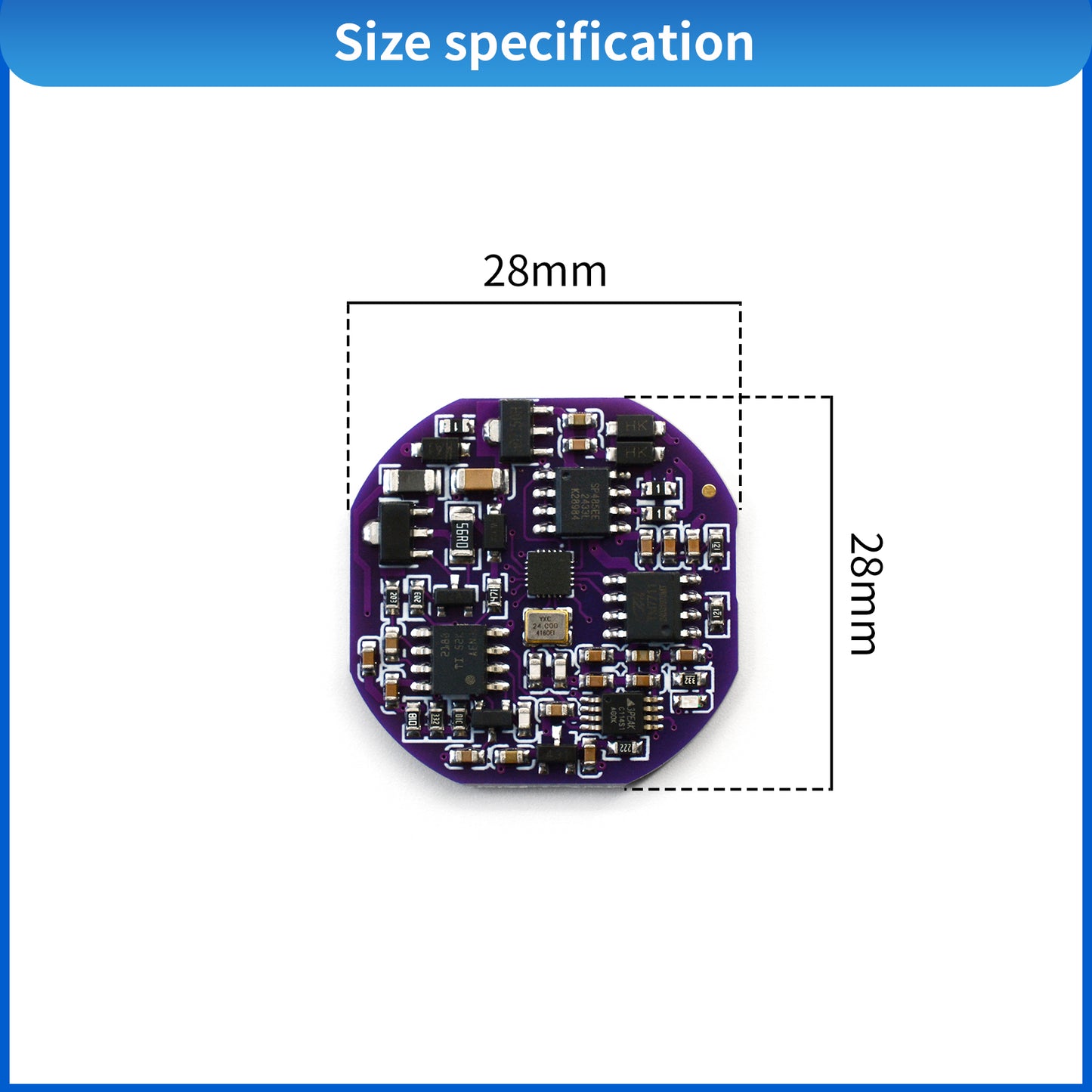

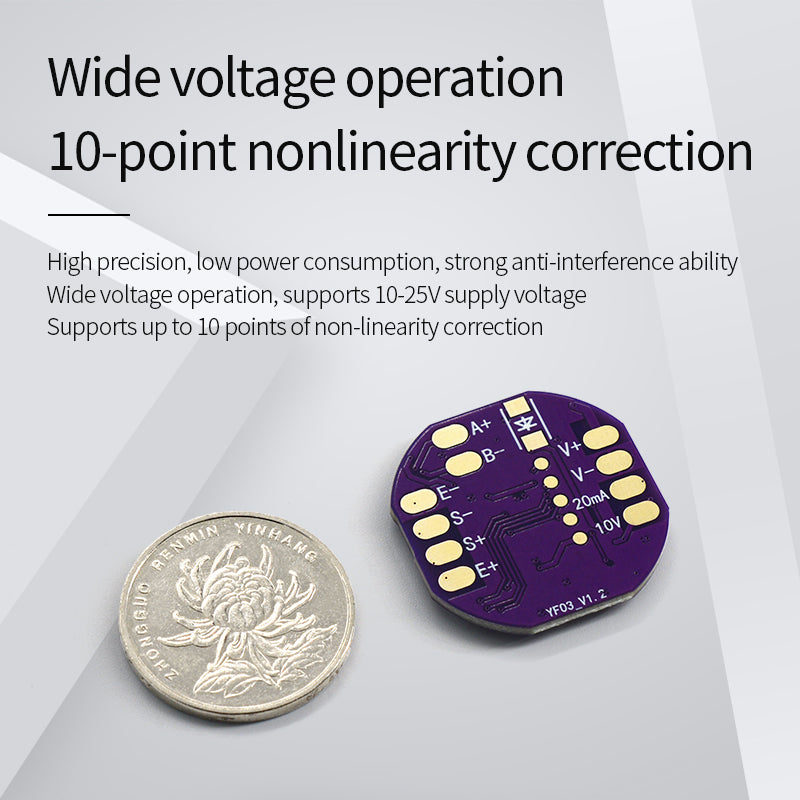

(2) Lightweight and Easy to Integrate

The module weighs approximately 0.1 kg, is compact and lightweight, and can be easily embedded into various weighing equipment or narrow spaces in automated production lines. Whether integrated into high-precision electronic scales or sensor arrays in large weighing platforms, it can be seamlessly adapted, enabling equipment to achieve miniaturization and compact design.

4. Precise Measurement and Control, Top-Notch Data Quality

(1) Precise Excitation and Conversion

The sensor excitation voltage is stabilized at DC5V±0.1V (maximum 200mA), providing reliable power to the weighing sensor; Using 24-bit AD conversion with 1/10,000 stability precision, it can precisely capture subtle weight changes, converting sensor signals into high-quality digital data. This ensures that data errors are kept within an extremely low range across weighing scenarios from 5kg to heavy loads, providing precise reference data for production and testing processes.

(2) Multiple speed settings to accommodate different requirements

Measurement speeds include 10Hz / 40Hz / 600Hz / 1200Hz (default 10Hz) Multiple rates available, combined with ±0.05% F・S nonlinear error, whether for static high-precision weighing (such as laboratory sample testing), dynamic rapid weighing (such as logistics vehicle weighing), or continuous measurement on assembly lines, modes can be flexibly switched to efficiently collect and accurately reproduce weight data, adapting to diverse measurement and control rhythms.

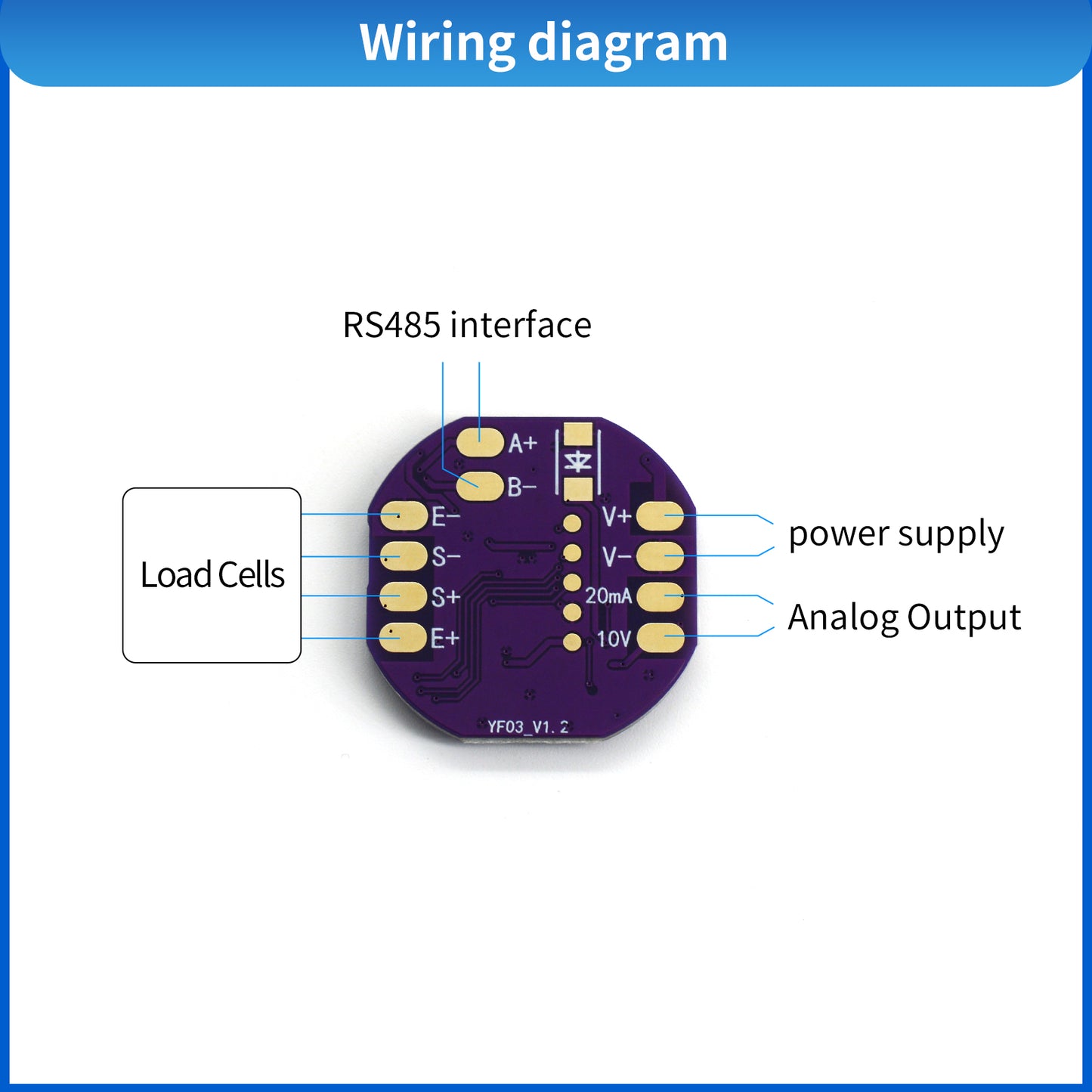

5. Convenient communication and excellent compatibility and expandability

(1) Standard communication configuration

Adopts an RS485 non-isolated communication interface with Modbus-RTU communication protocol, default baud rate of 38400 (supports adjustment to 115200), and supports multiple parity options including no parity (default), odd parity, and even parity. Seamlessly integrates with mainstream PLCs, industrial computers, and upper-level systems, quickly integrating into existing industrial communication networks to achieve real-time transmission of weighing data, remote monitoring, and multi-device collaboration, helping enterprises build intelligent weighing and measurement control systems.

Share

Product details

Product details